THE STORY

An international container glass producer with 2 production sites in the Netherlands noted that the energy consumption in the annealing lehrs was very different.

Situation in the 2 different factories

Site 1 uses several different brands of annnealing lehrs, the consumption is noted per lehr electronically on a daily basis. The yearly figures showed that the Glaseco (now G-Lehrs) annealing lehr consumed 40 % less energy per ton melt than the factory average.

The consumption of our lehr was (on a yearly basis) 50 Mjoule / ton melt, the nearest other lehr was at 77 Mjoule / ton melt.

Site 2 used in both lines the same type of annealing lehr from an international well-known brand, the consumption was not measured but people were aware that it was quite high.

Modifying the annealing curve

Site 1 measured already the gas consumption and started to also measure accurately the annealing quality. As a result the consumption could be lowered by modifying the annealing curve, a time consuming procedure.

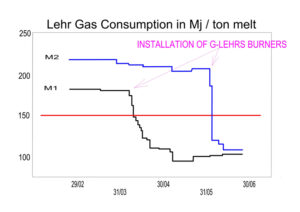

Site 2 started to measure accurately the consumption and also the annealing quality.

The annealing curve was optimised and resulted in a gas consumption economy of 30 %. Nevertheless the energy consumption still was rather high : 170 Mjoule / ton melt.

Final solution

Site 1 the results of the actions are accepable to good and the actual actions continue.

Site 2 we made a study and at our advise the existing burners were replaced with our G-Lehrs burners. At first only the burners in line M1 were replacerd but after installation and monitoring the burners in line M2 were immeditely replaced too.

The installation of G-Lehrs burners reduced the gas consumption by 40 to 50 %.

The payback time of the investment was less than 6 months.

– Replacing the existing burners was done while production continued.

– Alarms etc. function as before.

– Months of flawless functioning (a burner alarm became a curiosity) proves that

G-Lehrs burners are very reliable and need less maintenance.

Conclusion

Replacing your existing burners with G-Lehrs burners always results in lower consumption. (not always to this extend, 40 > 50 % as above is exceptional, 20 > 30 % in most cases).

CONTACT US TO MAKE THE CALCULATION FOR YOUR SITUATION.